Understanding the key differences between these two prominent printing technologies is crucial for apparel business owners before investing in equipment and training. In this guide, we’ll cover everything you need about conventional DTG printing vs screen printing for t-shirt decoration and customization.

Table of Contents

Introduction

With the growth of the custom apparel industry, t-shirt business owners have more options than ever for printing graphics and designs onto garments. The two most common printing technologies are direct-to-garment (DTG) printing and screen printing. Understanding the core differences between these methods is crucial for selecting the right process based on order quantities, design complexity, production timelines, operating costs, and more.

What is Screen Printing?

Screen printing is a printing process whereby ink is transferred through a mesh screen stencil onto a substrate such as fabric, paper, plastic, etc. The stencil openings determine the image area, allowing ink to permeate the substrate in desired areas.

Step-By-Step Process

- The artwork is created and output into film positives.

- Screen mesh is tightly stretched across a frame.

- The light-sensitive emulsion is applied to the screen and dried.

- The positive film is placed under the screen and exposed to a UV light.

- Ink-blocking stencil areas harden, while non-image areas wash out.

- Ink is placed on the screen, and a squeegee presses it through the open mesh.

Types of Inks and Equipment

Common inks include plastisol and water-based. Manual and automatic presses allow high-volume production. Other equipment like exposure units, washout booths, and drying systems complete a typical screen printing shop setup.

Pros of Screen Printing

- Very cost-effective for bulk orders

- Bold, bright-colored prints

- Suitable for fabrics like T-shirts

- Durable prints lasting years

Cons of Screen Printing

- Time-consuming setup and stencil creation

- Limited fine detail and color reproduction

- Fixed setups per color make short runs expensive

What is DTG Printing?

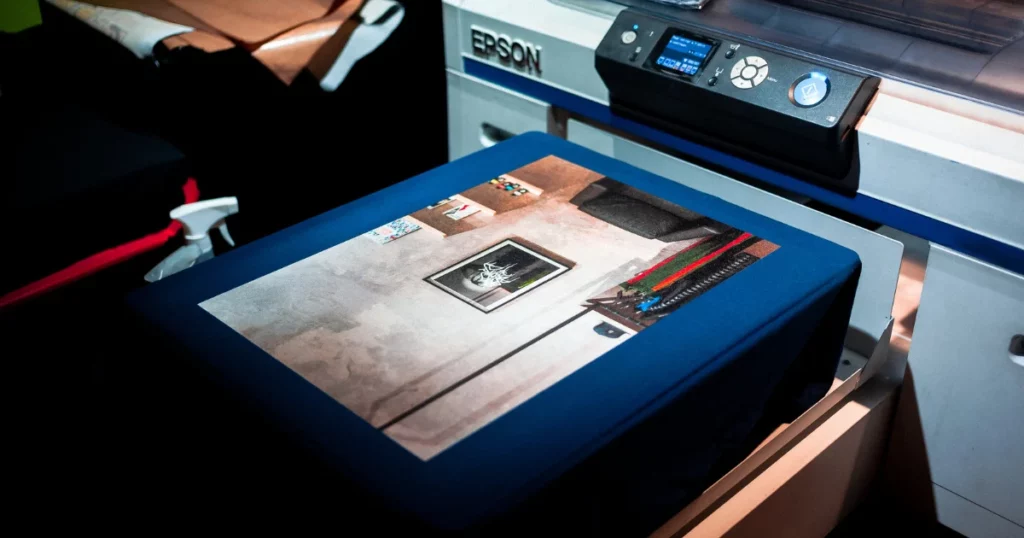

DTG printing, also known as direct-to-garment printing, is a process of printing full-color digital images directly onto textiles and garments using specialized inkjet printers.

How DTG Printing Equipment Works

A DTG printer is an industrial inkjet printer optimized for printing directly on textiles. The printer has a flat platen and printable area large enough to accommodate a t-shirt, hoodie, or other garment. Designs in full color are printed directly onto the fabric using water-based pigment inks.

Step-by-Step DTG Printing Process

- The digital design file is prepared, processed for the printer, and loaded into the printer software.

- The garment is loaded onto the printer platen either manually or using an automatic loader.

- A pretreatment solution is applied to the fabric to prepare it for ink absorption.

- The design is then printed directly onto the pretreated fabric using CMYK pigments.

- The garment is removed, post-treatment solutions applied, and the print cured using a heat press.

Pros of DTG Printing

- Photorealistic, full-color prints

- No minimum order quantity

- Ideal for customization and personalization

- Soft hand feel after printing

- Can print on light or dark-colored garments

Cons of DTG Printing

- Slow production speed compared to screen printing

- Higher ink costs per print

- Pretreatment and post-treatment add additional steps

- Fades faster than screen printing over time

Read more about: Best Print on Demand Tools for Your Business in 2024

DTG Printing vs Screen Printing – Print Quality Comparison

1. Color and Detail

DTG printing can achieve photorealistic, continuous tone prints with subtle gradients and shading thanks to the inkjet process laying down small dots of CMYK ink. Screen-printed designs have a more stylistic, poster-like aesthetic with bold, solid spot colors without blends.

2. Print Durability

Screen-printed ink bonds to the fibers of the garment, resulting in a very durable print that resists fading, cracking, or peeling even after repeated washings. DTG prints last through dozens of wash cycles but may slowly fade over time.

3. Fabric Feel and Hand

DTG leaves a very soft feel and breathability largely unaffected. However, the thicker ink deposited from screen printing can result in some surface texture and increased stiffness. DTG is better for comfort, screen printing provides more durability.

4. Print Size, Placement, and Special Effects

One of DTG’s advantages is the ability to print edge-to-edge full front and back designs reliably. Screen printing requires spacing from seams. Special effects like metallic silver or gold inks and simulated distressing are easier with screen printing.

DTG Printing vs Screen Printing – Cost Analysis Comparison

1. Equipment and Startup Investment

DTG printers have a lower startup cost than screen printing equipment. A basic DTG printer can be purchased for under $10,000 whereas an entry-level screen printing press with a washout booth, exposure unit, and other essentials often exceeds $30,000.

2. Recurring Operational Costs

The ink and pretreatment fluids for DTG printing are more expensive per liter compared to plastisol inks for screen printing. However, DTG inks are only applied to the printed area vs coating the entire garment, making overall ink costs per print more favorable. Other maintenance costs are similar.

3. Cost Per Print/Per Garment

For small to medium quantity orders from 12 to 36 pieces, DTG printing is significantly more affordable. The ability to print white ink and dark garments further adds value to custom orders. However, screen-printed shirts can be produced for under $2 per piece for order quantities above 100.

4. Economies of Scale and Break-Even

Screen printing costs go down dramatically with order size due to stencil reuse and ink efficiencies. The break-even point vs DTG is around 36 pieces. Beyond this point, screen printing becomes increasingly cost-effective. DTG maintains consistent pricing regardless of quantity.

5. Profit Margins

DTG printing offers higher profit margins on small custom orders by eliminating setup charges. But screen printing provides up to 70% margins on large production runs. An integrated printing strategy allows for maximizing profits.

Create customized designs with mockey.ai for the products you want to sell online including t-shirts, phone cases, tote bags, and more.

DTG Printing vs Screen Printing: Which is Better?

1. Print Quality

DTG printing utilizes specialized inkjet printers to print full-color graphics directly onto the fabric. The prints are extremely high resolution and replicate digital artwork with precision, including photographic images. With no color restrictions and unlimited detail, DTG excels at photorealistic prints.

Screen printing uses thicker plastisol inks pressed through fine mesh screens. The prints have bolder, more vibrant colors with a raised texture. However, blending and gradients are limited, and fine details can be difficult to reproduce compared to DTG prints.

Winner: DTG printing for photorealistic quality, screen printing for bold colors

2. Cost Efficiency

The equipment cost for an entry-level DTG printer starts at around $10,000 compared to a few thousand for a starter screen printing kit. But DTG has no minimum order requirements or setup fees per design. Combined with the lack of wasted ink on screens or films, this makes DTG extremely affordable for small-batch orders.

At higher quantities, screen printing benefits from major economies of scale. Ink and operational costs per print drop exponentially the more prints are produced. For businesses focused on high-volume orders, screen printing provides unbeatable cost efficiency.

Winner: DTG printing for small batches, screen printing for bulk orders

3. Order Quantities

A major perk of DTG printing is print-on-demand capability. With no minimum orders or setup fees, DTG empowers businesses to profitably print a single shirt or small batches in any design. This facilitates easy online order fulfillment for customized apparel.

Screen printing requires creating films and preparing screens for every color in a design. This lengthy process means minimum orders are enforced, usually between 12 to 24 shirts. While ideal for large runs, screen printing lacks flexibility for short batches.

Winner: DTG printing for singles and dozens, screen printing for hundreds or more

4. Production Workflows

Going from graphic design to printed shirts, DTG printers have minimal steps. The artwork is set up in software and then printed directly onto a pretreated shirt. With no screens, inks, or films to prepare, the DTG process requires no labor-intensive setup.

Alternatively, screen printing has a lengthy pre-production workflow before high-speed printing begins. This includes separating colors, preparing film positives, and burning and washing screens. But once setup is complete, screen printers have very fast print speeds.

Winner: DTG printing for fast setup, screen printing for high throughput

Read more about: Types of T Shirt Printing: The Ultimate Guide (2024)

Which is Right for Your T-shirt Business?

When to Use DTG Printing

DTG, or direct-to-garment printing, is ideal for:

- Smaller quantity orders

- Frequent design changes

- Photographic or complex multicolor prints

- Dark colored shirts

Since there are no setup costs, DTG allows you to print a single shirt or small batches cost-effectively. The process can easily handle detailed designs in full color on both light and dark fabrics. This makes it a versatile solution for custom t-shirt orders.

When to Use Screen Printing

Screen printing is better suited for:

- Large-quantity batch orders

- Simple designs with limited colors

- Printing on light-colored shirts

While screen printing has higher setup costs, the per-unit price becomes very low for bulk orders. It can efficiently print large quantities of shirts with simple spot-color designs. However, intricate multicolor designs may be more complex and expensive to set up.

Integrating Both Printing Methods

Most t-shirt businesses find it beneficial to offer both DTG and screen printing options. This allows them to handle a wider variety of order sizes and design complexities cost-effectively.

DTG is used for small custom orders and complex prints needed quickly or in small quantities. Screen printing handles large production runs of shirts with simple spot color designs where per unit cost needs to be very low.

By properly integrating both digital DTG printing vs screen printing into your production workflow, you gain the versatility to deliver exceptional results regardless of order specifics. This provides the best value to your customers while maximizing profitability.

Conclusion

In summary, DTG printing vs screen printing each have distinct advantages. DTG provides photorealistic, customizable prints ideal for low quantities and short turnarounds. Screen printing excels at bold, eye-catching graphics that are most economical for high-volume bulk orders.

| Basis | DTG Printing | Screen Printing |

| Print Quality | Photorealistic, unlimited colors, fine details | Bold, bright spot colors, simple designs |

| Cost Efficiency | Lower startup costs, higher ink expenses, no minimum orders, higher profit margins on small runs | Moderate startup costs, lower ink costs, dozens minimum, thinner margins |

| Order Quantities | Ideal for singles and short runs, on-demand fulfillment, fully customizable | Optimized for bulk orders, high setup time, some design limitations |

| Production Factors | No setup time, slower print speeds | Lengthy setup, very fast print speeds |

| Types of Graphics | Photographs, complex illustrations, full-color artwork | Logos, simple designs, spot color graphics |

In determining the best t-shirt printing method for your business, consider your average order quantities and graphic styles. DTG is ideal for short runs, and custom/photorealistic prints. Screen printing excels at long runs and simple spot color prints. Many t-shirt companies utilize both printing methods to capitalize on these strengths. Combining DTG printing vs screen printing provides the most versatility for offering short-run custom orders and higher-volume bulk orders.

FAQs on DTG printing vs screen printing

What is the difference between DTG printing vs screen printing?

DTG (direct-to-garment) printing uses specialized inkjet printers to print full-color graphics directly onto the fabric. Screen printing uses screens and stencils to print ink through a mesh onto the shirts.

Which method produces better print quality – DTG printing vs screen printing?

DTG printing produces photorealistic, full-color prints with unlimited detail and no color restrictions. Screen printing can deliver bold, bright spot colors but has some limitations on fine detail.

DTG printing vs screen printing which is more cost-effective for t-shirt printing?

For small order quantities, DTG is more affordable because there are no setup fees. For large bulk orders, screen printing becomes drastically cheaper on a per-unit basis.

Which printing method is better for short runs vs large orders?

DTG is ideal for short runs since there is no setup time or cost. Screen printing has high initial setup costs so is better suited for large order quantities, usually dozens or multiples thereof.

What types of ink and equipment are used in DTG vs screen printing?

DTG printers use specialized inkjet inks and cartridges. Screen printing uses thicker plastisol inks and requires screens, squeegees, exposure units, and washout booths.

How durable are DTG-printed t-shirts compared to screen printing?

With proper pretreatment, DTG prints can match screen print durability and last through dozens of washes. But screen-printed ink sits on top of the garment and may resist cracking better over time.

What fabric types work best for DTG vs screen printing?

DTG works well on 100% cotton and a cotton/polyester blend. Screen printing works on cotton, polyester, blended fabrics, even leather and other materials.

How customizable are the prints for each printing method?

DTG offers full customization of designs in terms of size, placement, colors, etc. Screen printing allows customization but is more limited by several colors and levels of detail.

What are the setup and production times for DTG vs screen printing?

DTG printers are slower, producing around 30 shirts per hour. Screen printing has a lengthier setup but very fast print speeds of hundreds per hour.

What are the limitations of DTG printing vs screen printing?

DTG struggles with very dark fabric colors and has higher ink costs. Screen printing is limited in detail, number of colors, and short-run efficiency.